Velo3D, Inc. (NYSE: VLD), a leading metal additive manufacturing technology company for mission-critical parts, today announced its Sapphire family of 3D printers are the first to achieve the U.S. Department of Defense’s (DoD) Green-level STIG (Security Technical Implementation Guide) Compliance. The certification allows Sapphire printers to be connected to the DoD’s Secret Internet Protocol Router Network (SIPRNet) and gives customers the confidence their metal 3D printers are hardened against potential cyberattacks.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20231205745835/en/

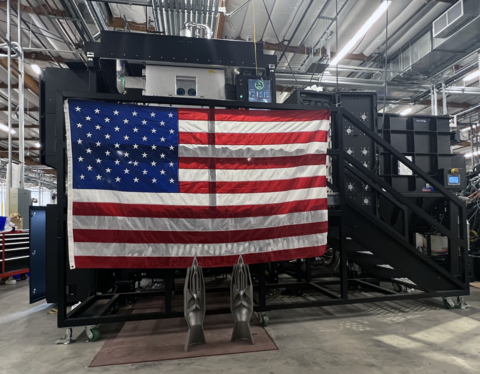

A large-format Sapphire XC printer in Velo3D’s Lakeview, California facility, along with a cross-sectioned supersonic ramjet engine. Velo3D printers are compliant with the U.S. Department of Defense’s STIG cybersecurity guidelines, giving customers the confidence their additive manufacturing technology is hardened against cyberattacks and other vulnerabilities. All Velo3D printers are designed and manufactured in the U.S.A. (Photo: Business Wire)

The rigorous qualification process was achieved through collaboration with a third party to generate compliance, vulnerability, and remediation reports from Sapphire printers that measure against security benchmarks. The testing process confirmed that all Velo3D printers provide the highest network, data, and software security, as well as vulnerability management, reducing the risk of security breaches. This includes Sapphire, Sapphire 1MZ, Sapphire XC, and Sapphire XC 1MZ. Test results indicated Velo3D achieved an average score of 97% on its tests, exceeding the DoD’s threshold of 90% needed to achieve Green-level STIG compliance—the highest level offered.

“Our team at Velo3D strives to go above and beyond to meet our customers’ needs, so when customers that work with the DoD inquired about STIG compliance, we quickly went to work to achieve the highest level of certification available,” said Benny Buller, Velo3D Founder and CEO. “I am proud of our team’s work in achieving this qualification and I am confident this will empower all our customers—but especially those that work with the DoD and other government agencies—to fully leverage the capabilities of our additive manufacturing technology without worrying about the risk of stolen intellectual property.”

In addition to being SIPRNet-ready, Velo3D Sapphire printers can now also connect to the DoD’s Non-classified Internet Protocol Router Network (NIPRNet). STIG compliance is required for DoD agencies and contractors that connect to both networks, as well as networks operated by other branch departments of the federal government.

Without STIG compliance, government agencies and contractors using metal 3D printers were required to keep them disconnected from network connections. This technique—commonly referred to as airgapping—can complicate the process of managing printers. In the case of Velo3D, engineers and printer operators could not fully leverage the capabilities of its fully integrated solution, which enables users to easily monitor the printing of parts, analyze the data generated in the printing process, and transfer print files to and from printers. Now, with Velo3D, engineers can utilize all aspects of metal additive manufacturing technology when manufacturing parts that are classified or International Traffic in Arms Regulation (ITAR) protected, without risking stolen intellectual property or other cyberattacks.

STIG compliance will also make it easier for defense contractors and agencies to purchase Sapphire printers as they will no longer have to obtain exceptions and other approvals that are required for non-compliant printers. Current Velo3D customers can easily upgrade their existing Sapphire printers to achieve STIG Green-level security. The software upgrade can be completed with minimal impact on the customer.

Resources:

- To learn more about Velo3D’s STIG certification and the process followed to achieve compliance, read the blog by Aaron Katske, Vice President of Information Technology.

- For more information about Velo3D’s fully integrated solution, visit velo3d.com.

- Visit the DoD’s public Cyber Exchange for more information on STIGs.

About Velo3D:

Velo3D is a metal 3D printing technology company. 3D printing—also known as additive manufacturing (AM)—has a unique ability to improve the way high-value metal parts are built. However, legacy metal AM has been greatly limited in its capabilities since its invention almost 30 years ago. This has prevented the technology from being used to create the most valuable and impactful parts, restricting its use to specific niches where the limitations were acceptable.

Velo3D has overcome these limitations so engineers can design and print the parts they want. The company’s solution unlocks a wide breadth of design freedom and enables customers in space exploration, aviation, power generation, energy, and semiconductor to innovate the future in their respective industries. Using Velo3D, these customers can now build mission-critical metal parts that were previously impossible to manufacture. The fully integrated solution includes the Flow print preparation software, the Sapphire family of printers, and the Assure quality control system—all of which are powered by Velo3D’s Intelligent Fusion manufacturing process. The company delivered its first Sapphire system in 2018 and has been a strategic partner to innovators such as SpaceX, Honeywell, Honda, Chromalloy, and Lam Research. Velo3D has been named as one of Fast Company’s Most Innovative Companies for 2023. For more information, please visit Velo3D.com, or follow the company on LinkedIn or Twitter.

Forward-Looking Statements:

This press release includes “forward-looking statements” within the meaning of the “safe harbor” provisions of the Private Securities Litigation Reform Act of 1996. The Company’s actual results may differ from its expectations, estimates and projections and consequently, you should not rely on these forward-looking statements as predictions of future events. Words such as “expect”, “estimate”, “project”, “budget”, “forecast”, “anticipate”, “intend”, “plan”, “may”, “will”, “could”, “should”, “believes”, “predicts”, “potential”, “continue”, and similar expressions are intended to identify such forward-looking statements. These forward-looking statements include, without limitation, the Company’s goals for 2023 and the Company’s other expectations, hopes, beliefs, intentions, or strategies for the future. These forward-looking statements involve significant risks and uncertainties that could cause the actual results to differ materially from the expected results. You should carefully consider the risks and uncertainties described in the documents filed by the Company from time to time with the SEC. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Most of these factors are outside the Company’s control and are difficult to predict. The Company cautions not to place undue reliance upon any forward-looking statements, including projections, which speak only as of the date made. The Company does not undertake or accept any obligation to release publicly any updates or revisions to any forward-looking statements to reflect any change in its expectations or any change in events, conditions, or circumstances on which any such statement is based.

Velo, Velo3D, Sapphire, and Intelligent Fusion, are registered trademarks of Velo3D, Inc. Without Compromise, Flow and Assure, are trademarks of Velo3D, Inc.

All Rights Reserved © Velo3D, Inc.

View source version on businesswire.com: https://www.businesswire.com/news/home/20231205745835/en/