Today, 24M unveiled a transformative new battery separator — 24M ImpervioTM — that promises to redefine battery safety for electric vehicle (EV), energy storage systems (ESS) and consumer applications. This proprietary technology enables unprecedented safety advancements for lithium-ion and lithium-metal batteries that will facilitate the prevention of catastrophic fires and massive recalls caused by metallic dendrites (i.e. dendrites from metal contamination introduced during the production process), electrode misalignments or lithium dendrites. 24M ImpervioTM achieves these results by obstructing metallic dendrite formation, as well as by measuring battery performance thereby enabling early fault detection.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20240108971229/en/

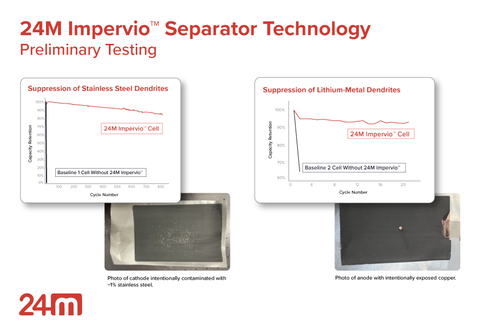

24M internal comparison tests of baseline cells, NMC/graphite cells without Impervio™, against identical cells with Impervio™, demonstrated the significant safety advantages of the Impervio™ cell. (Graphic: Business Wire)

“The sweeping safety improvements demonstrated by 24M ImpervioTM are essential to meet the growing demand for EV and ESS, which rely on next-generation battery technologies,” said 24M CEO Naoki Ota. “It will open up a whole new world of growth for battery-driven applications by eliminating the fear of catastrophic safety failures.”

“For many years safety challenges have limited the commercial viability of the most promising next-generation cell chemistries,” commented 24M Chief Scientist and MIT Professor Yet-Ming Chiang. “The ability to prevent dendrites and detect internal faults that 24M ImpervioTM has shown can enable the commercialization of a new class of large area, high energy density batteries based on lithium-metal and silicon-dominant chemistries.”

While lithium-ion continues to be the preferred battery chemistry, it’s been plagued by safety challenges, including the formation of dendrites — metal structures that can build up on the anode surface potentially shorting the battery cell, which can lead to fires. The 24M ImpervioTM technology prevents this with a fail-safe approach to battery safety by:

- Dendrite prevention: Starts at the source with a proprietary separator technology that impedes the growth of dendrites.

- Early fault detection: 24M ImpervioTM continuously monitors the cell and can detect a potential short before it occurs and enables a safe discharge and shutdown of the individual battery cell. This will also prevent the mass recall of products by pinpointing defective products and recalling only those.

- Integrates with lithium-metal and conventional lithium-ion batteries: 24M ImpervioTM offers the same safety benefits for conventional lithium-ion and lithium-metal cells as it does for 24M SemiSolidTM cells.

Preliminary Testing

24M internal comparison tests of baseline cells, NMC/graphite cells without ImpervioTM, against identical cells with ImpervioTM, demonstrated the significant safety advantages of the ImpervioTM cell.

In one test, the cathode of the baseline and ImpervioTM cells were each intentionally contaminated with ~1% stainless steel. This caused the baseline cell to short immediately after formation, while the ImpervioTM cell, under the same conditions, suppressed the stainless steel dendrite and surpassed 800 cycles with a capacity retention of over 83%.

In a second test, the baseline and ImpervioTM cells intentionally exposed copper on the anode to stimulate the formation of a lithium-metal dendrite. This led to a rapid soft short of the baseline cell, while the ImpervioTM cell suppressed the lithium-metal dendrite and delivered stable coulombic efficiency during cycling — meaning no soft short between the cathode and anode.

24M expects to fully demonstrate mass production of ImpervioTM by the end of 2024 and introduce it to the market in 2025 or 2026. 24M is currently working in collaboration with volume production partners and license partners for initial product launch.

This latest 24M innovation comes on the heels of the company’s launch of its transformative electrode-to-pack battery technology — 24M ETOPTM — which sets the foundation for unmatched system energy density. With the introduction of these new technologies, 24M is moving beyond its core technology — the 24M SemiSolidTM and Unit Cell manufacturing platform — and offering a revolutionary technology set that enables a better energy future.

To learn more about these innovations and more, visit 24-m.com or these upcoming industry events:

- January 9 to 12 at CES: Las Vegas Convention Center North Hall, booth 10937

- February 19 to 22 at NAATBatt 2024 Building Capacity Conference

About 24M

24M answers the world’s need for affordable energy storage by offering a revolutionary battery manufacturing and product design technology set enabled by the 24M SemiSolid™ and Unit Cell manufacturing platform. By re-inventing today’s battery products and manufacturing methods, 24M solves the critical, decades-old challenge associated with the world’s preferred energy storage products and technologies: reducing their high cost while improving their performance, safety and recyclability. Founded and led by some of the battery industry’s foremost inventors, scientists and entrepreneurs, 24M is headquartered in Cambridge, Mass. For more information, please visit www.24-m.com.

24M® is a registered trademark of 24M Technologies, Inc.

Impervio™, 24M SemiSolid™ and 24M ETOP™ are pending trademarks of 24M Technologies, Inc.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240108971229/en/